Assembly, Print & Packaging

Made in germany / Services

Assembly, Print & Packaging – our extensive service

We take it that you not only want the produced injection moulded part but also other supplementary work & services to minimize your outlay and costs. We can support you in that. Along with our core competence, our portfolio includes practical, complementary services.

We would happily handle the surface finish of your injection moulded parts for use directly without any complex interim steps. We have a flexible set-up in module assembly and could take on all your manual work. Our other services include storage, dispatching your products and a varied packaging scope. All this, of course, is totally matched to your requirements.

Profile - Assembly, Print & Packaging

- Various printing operations

- Various paint finishes

- Hot stamping

- Laser labelling

- Ultrasonic welding

- Module assembly

- Manual work: De-burring, drilling, cutting, turning etc.

- Customized packaging

- Storage and dispatch

Surface finishing

Don’t your injection moulded parts need that finishing touch? Is so, then you’ll find our surface finishing services highly interesting. We’ll consult with you in detail and plan together how best to achieve your aims. Scratch resistance, weather-resistant, top optical characteristics – a lot is possible, we can discuss everything together.

Paint coating

The injection moulded parts often need a paint coating. Whether for functional or optical reasons. Varied paint coatings can be used for this. Just let us know your requirements; we’ll find the ideal solution to comply with your ideas.

Printing

We’ll recommend the ideal solution for your requirements profile and the plastic used from a number of printing processes. Whether it’s about font, logo or other symbols, small or large surface areas or for technical/optical purposes, we deploy the right printing process for each operational field.

Hot stamping

In hot stamping, pressure and heat transfer a paint coat onto the injection moulded part. In comparison, a hot stamping process is quickly applied and comes over well thanks to its low cost. We deploy hot stamping especially for one-tone coatings, logos and letterings. We coordinate the intended use and optical requirements with you and stamp your injection moulded parts as requested

Laser labelling

We use laser labelling for very fine labelling of injection moulded parts. It is highly appropriate for small fonts and symbols. We also use the technology for continuous numbering and serial numbers.

Chrome plating

We recommend chrome plating for those particularly high requirements placed on the optical characteristics and resistance. Your injection moulded parts are covered with a chrome coating which - depending on its application - is selected from various types. Along with that gleam, chrome plating extends the life of injection moulded part surfaces - thanks to greater resistance to scratches and temperature effects.

Ultrasonic welding

Ultrasonic welding has established itself in various applications and industries. It is used chiefly for thermoplastics. With rapid process times, maximum process dependability, precision-processing without extra substances such as adhesive, top quality and strength, ultrasonic welding unites those benefits which manifest themselves in a challenging profile on the joining technology. We match the highly flexible ultrasonic technology to your individual requirements and implement it flawlessly.

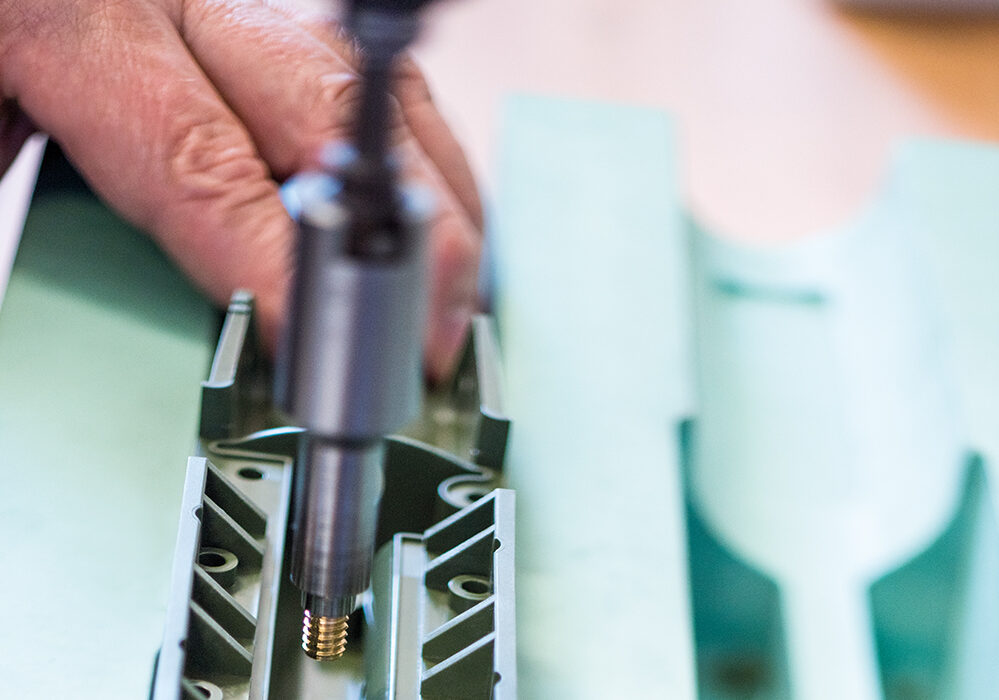

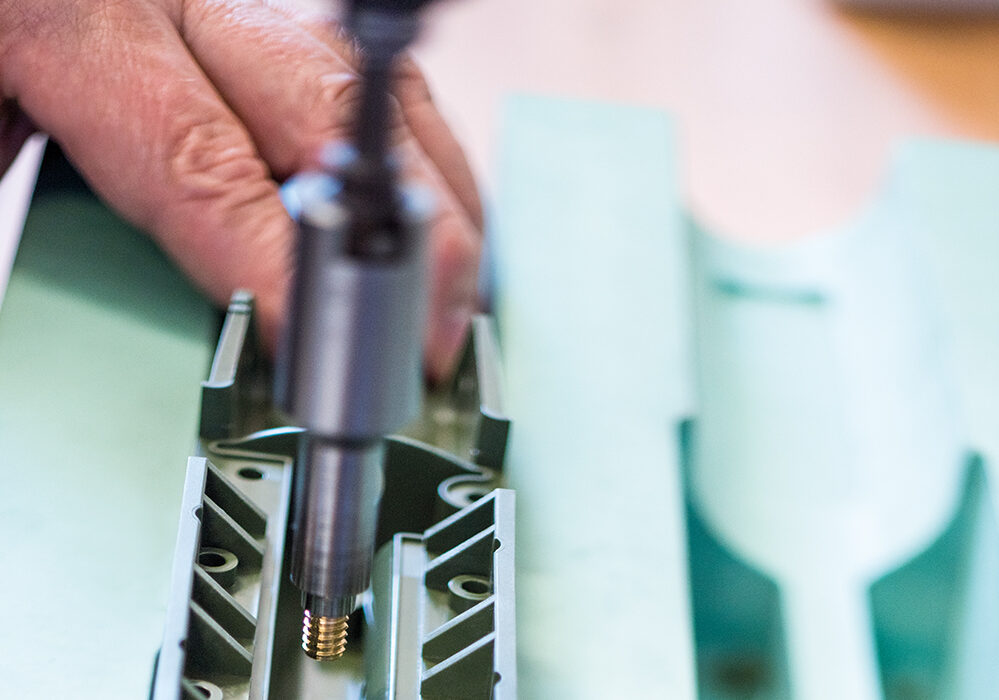

Module assembly and manual work

Our assembly department deals, for instance, with de-burring, drilling, milling and turning. Our work & services stretch from simple work through to assembling complex modules. You set down your requirements and we implement them.

In module assembly work, we precisely connect your injection moulded parts to external ones made up of the most varied material types. The result is that you obtain modules which fully satisfy your requirements.

We would also be happy to equip complete assembly points for you. The finish-assembled modules can still be packaged at AsMoPLAST and delivered just-in-time. We treat your requests as our marching orders. You can rely at all times on a smooth sequence of operations.

Store - logistics - packaging

Our storage capacities are available to store your products. Packaging, putting an order together and despatch are done to your requests. Just-in-time deliveries are, of course, possible.