Moulding in China – Consulting

Moulding in China / Consulting China

With AsMoPLAST to China –

you’ll sleep better!

Since 2001 we have been occupied with the Chinese market and since 2007 we have had our own site in China. There is nothing that we have not already see, heard and experienced. This immeasurable experience is decisive for our consulting quality regarding your projects in the Far East.

To be successful, it is vital that Chinese on-site conditions, mentality, conducting oneself and the structures are understood. It is even more important to know the right people and institutions. We know where to start, what needs to be considered and have a wide-spanning network. Thanks to numerous partnerships with inspected mould constructors, we provide the ideally matching solution for the most varied of requirements profiles.

AsMoPlast is per se your partner to avoid those risks in the production of injection moulding tools in China. We are there to advise on all projects in China.

Hallmarks mould construction and injection moulding China

Our location in China

guarantees a smooth

project sequence

We understand the character and

mentality, know all about the

structures and institutions

AsMoPLAST, as contractual

partner, is a strong

German company

Favourably priced, rapid,

suitable for all tests incl.

samples manufacture

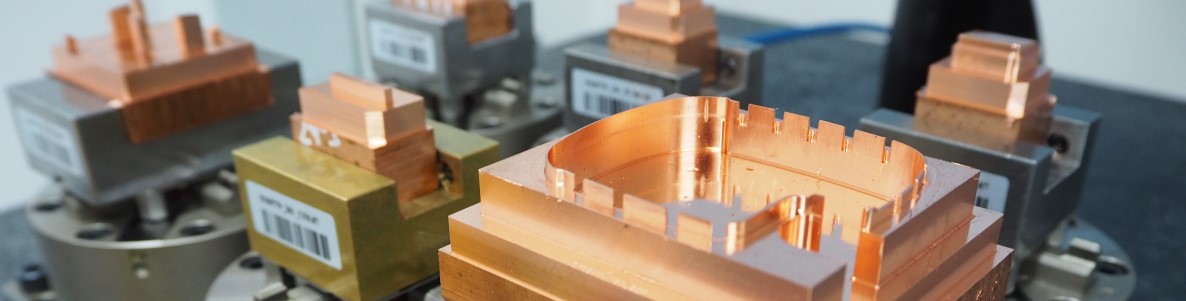

Injection moulding tools

for all requirements -

from simple to complex

Testing tools from China

at the injection moulding

centre

Project management

Selecting the right partners is crucial in global projects and in China, in particular. Only then can a smooth-running project management be ensured. We only place our faith in certificated companies which we are convinced will adhere to both the schedule and the required quality.

In the production phase we are continuously on-site thus ensuring professional project coordination, continuous monitoring of all processes and adherence to customer stipulations, specifications and schedules. AsMoPLAST’s project management puts nothing in the way of your success. The most important success factors of our global project management:

- Assuming complete project management

- Drafting project plans and continuous updating with definition, if required, of the requisite steps in the case of non-conformities

- Compilation of production systems

- Definition of change and optimization steps

- Layout and design meetings

- Project management with system partners

- Monitoring project schedules on-site at tool manufacturers and system suppliers

- Checking adherence to technical specifications

- Technical acceptance inspection of machinery, injection moulding tools and other equipment

- Monitoring start-up of production systems with active technical support