Prototype tools and samples

Made in germany / Prototype tools

Prototype tools and pre-series

You don’t want any expensive and time-wasting surprises in the production phase? Neither do we. That is why our prototypes and samples well ahead of the production start shield you from them. Thus there is no need for you to worry about tool manufacturing and series production.

Our Rapid Tooling services provide you with a host of possibilities. We practically fulfil every requirement you have in prototype tools and pre-series production. Injection tests in the original plastic, in various materials or colours, production of small to medium-sized lots under real-life conditions together with comprehensive function tests can all be carried out.

You can choose from several processes for production of injection moulding pre-series. Which is the right one for you cannot be simply stated as it depends on what you expect from the prototype. These expectations come, as a rule, from your injection moulded parts field of operations. We can manufacture both samples in the original plastic as well as rapid parts in the STL process. We of course consult you extensively on this.

Rapid tooling process - Prototype tools and samples in the original plastic

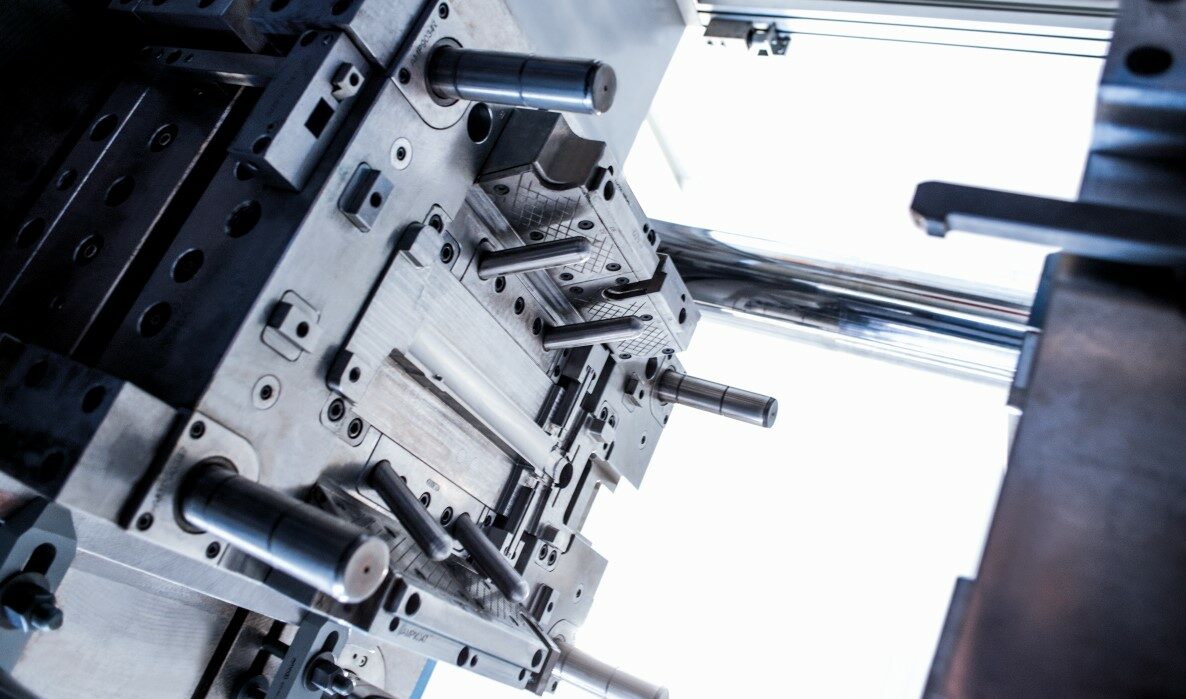

The prototype tools and samples allow all parameters to be precision-tested before the actual tool and series production starts.

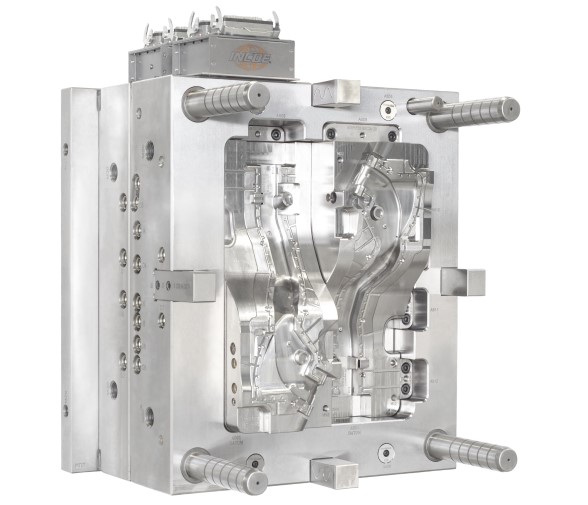

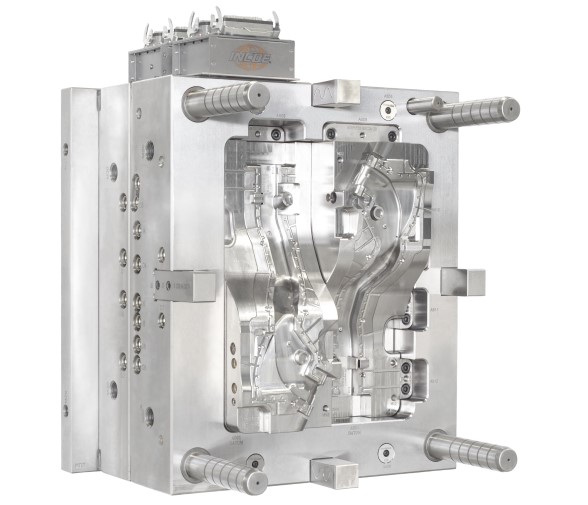

AsMoPLAST prototype tools

There are no limits for you in the production of prototype tools thanks to the AsMoPLAST dual system. We manufacture standard prototype tools at the production site in Endingen for you. For manufacturing complex prototypes we make use of the impressive technical infrastructure in China. We have the optimal solution for each function.

Samples in the original plastic

Our samples in the original plastic image the envisaged end products 1:1 technically, functionally and optically. As a result we can test complex units and sophisticated injection moulded parts. Even complex contours can be clearly imaged. Everything is tested - be it surface finish, technical features or specific stability requirements.

Any design shortcomings are detected and eliminated early on. Adjustments made to the mould tool and the product itself can be simply undertaken at any time. Everything can be easily adapted, changed or functionally optimized.

Rapid prototyping process (STL parts) - Stereo lithographic prototypes

In the STL process the choice of plastics and tests is somewhat limited. For instance, the thermal properties do not correspond to the series part. The greatest benefit of samples in the STL process is in their rapid manufacturing time.

That means: Requirements can be derived from the intended use. If a “simple” injection moulded part without a comprehensive requirements profile is to be rapidly tested, then producing the samples in the rapid prototyping process really becomes an interesting variant.

However, if an inspection of mechanical functions, the optical characteristics or full series suitability is expected, then prototypes from the STL process are not adequate. We will gladly advise you as to which variant should be considered for your intended use - whether sample parts in the original plastic or STL parts. We have the right process whatever the need.