Mould construction China

Moulding in China / Mould construction China

Practically unlimited opportunities in mould construction in China

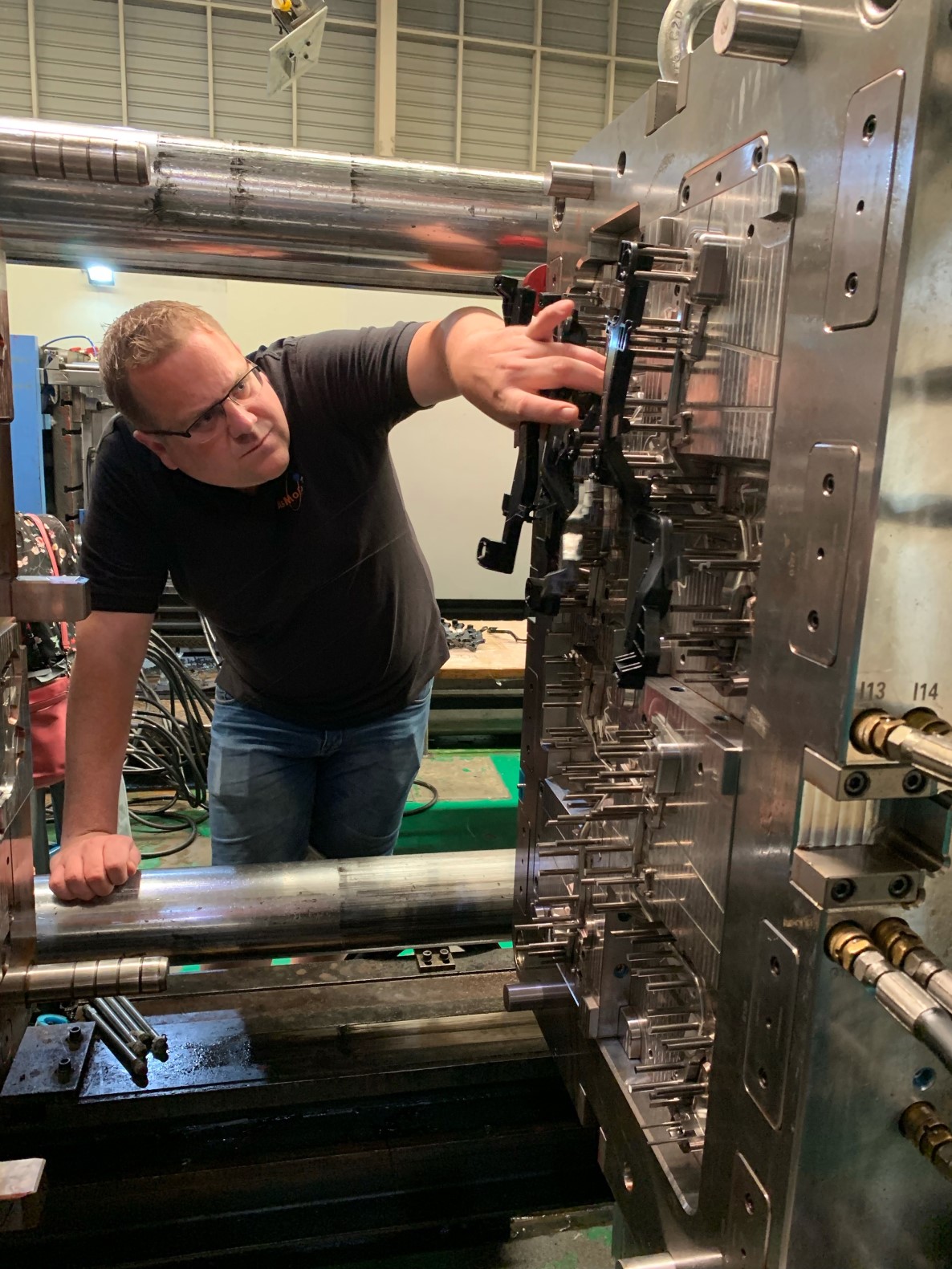

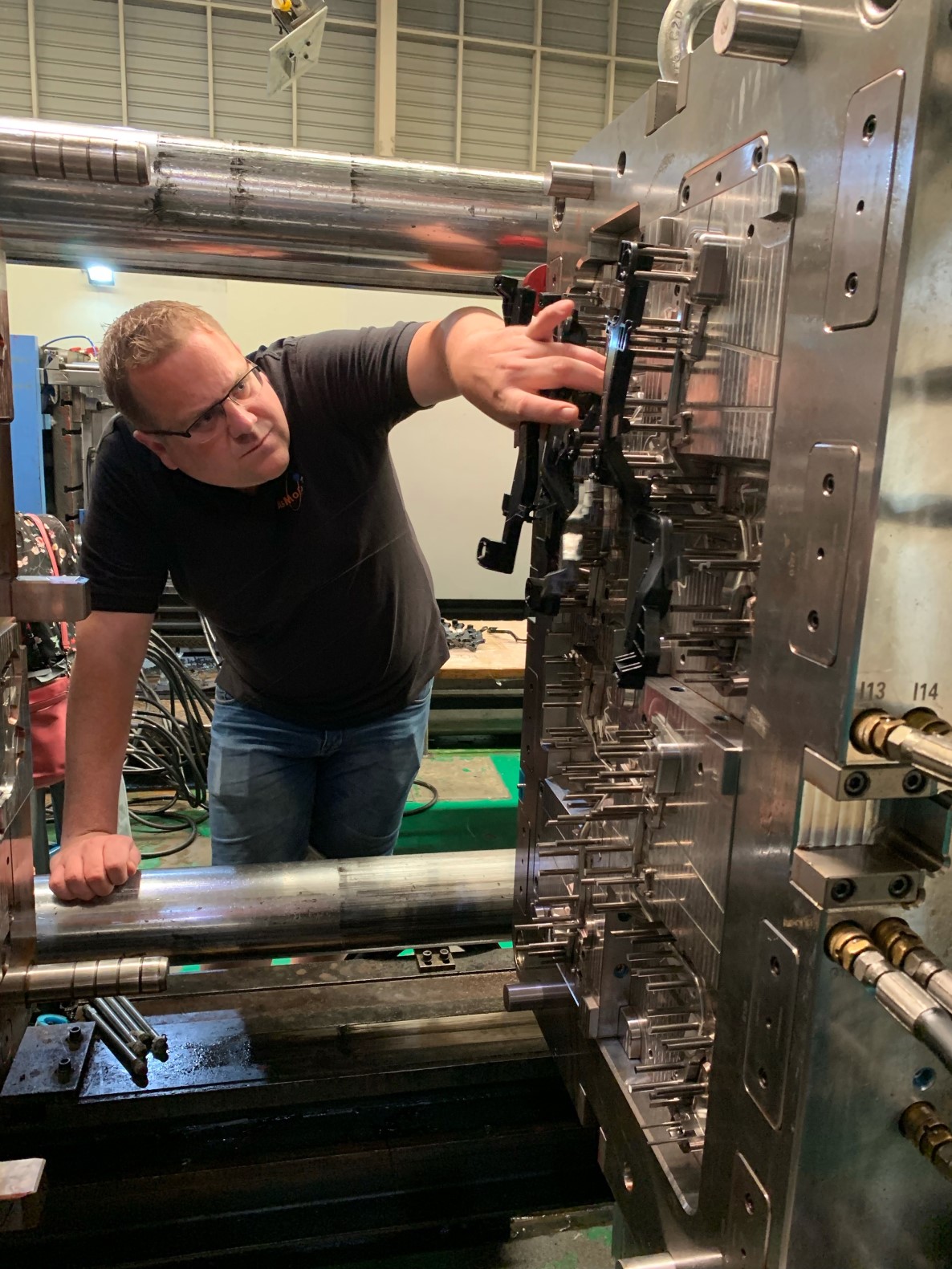

How good is mould and tool construction in China? Mould construction in China is recommended but coupled with a sense of proportion, know-how and experience! To turn projects into success stories requires a partner who has his roots in the national market and knows his way around in the Far Eastern economic area. That is precisely what AsMoPLAST stands for.

We have selected our mould construction partners in China with all due care and on the basis of important parameters: How are things thought through in the company? Is the company proprietor-managed? How does the CEO lead and organize things? What qualifications do the employees have?

All this and more have gone into our assessment system. We have sorted out the stable mould constructors in China and bound them to us. The result is you having exclusively selected and precision-checked manufacturing facilities to produce your injection moulding tools. One of the exclusive partnerships involves preferential treatment by AsMoPLAST and thus of yourself in cooperation.

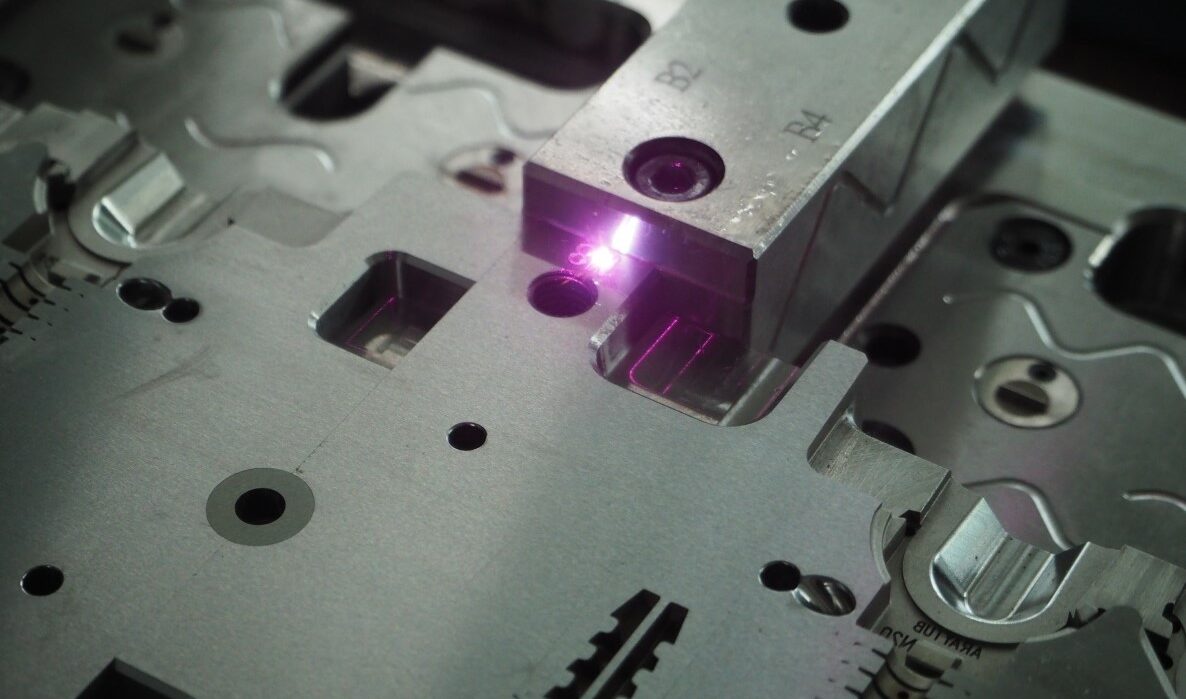

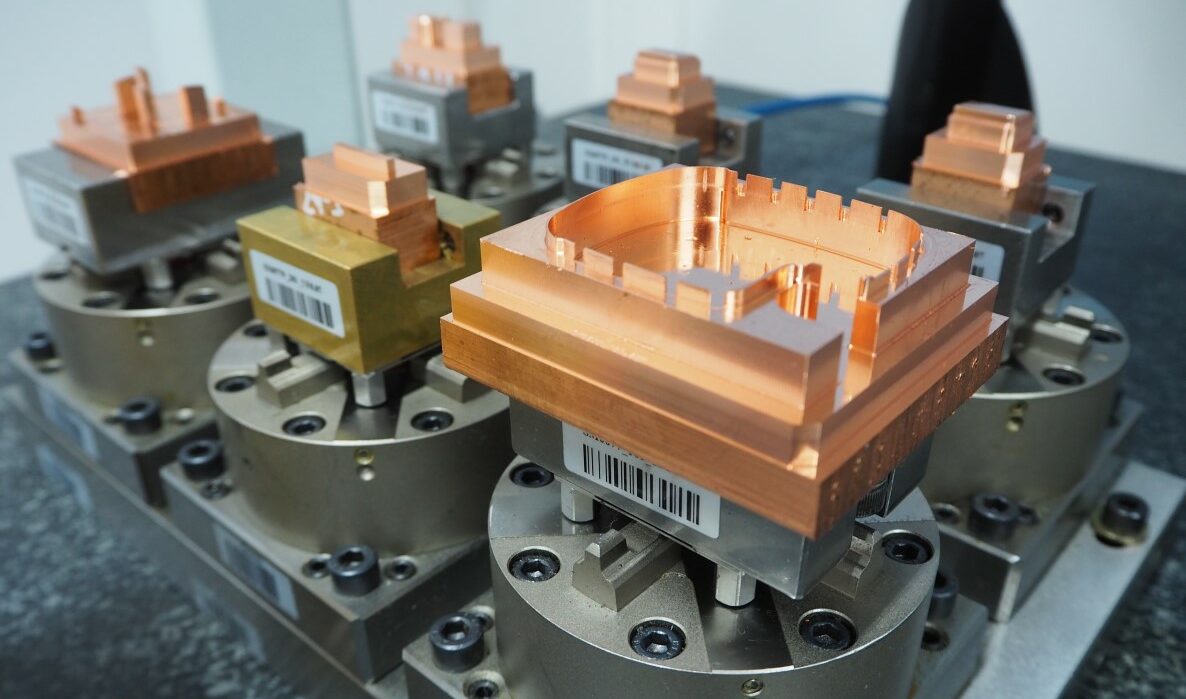

We have a DIN ISO 9001-based certificate for all injection moulds from China. State-of-the-art machinery and production of the European standard is guaranteed. And that is not all.

For each operational field, we mould technically demanding injection moulding tools of the best quality - varied as to the intended purpose and basically different in character. You obtain impressive competitive advantages in the price/performance ratio and in delivery/lead times.

AsMoPLAST lets you make use of all the chances in China and avoids all the risks.

Profile mould construction China

You receive an optimum mix of domestic, process-related know-how and Far-Eastern production. Long-time, validated contract partners, European standardized production and trained operation personnel ensure your injection moulding tools are reliably and faultlessly produced:

- Production of straightforward to highly complex injection moulding tools

- All production facilities are fully air-conditioned

- The sizes and precision of the injection mould tools leave nothing to be desired

- Blow moulds for the plastics industry

- Die casting moulds for the aluminium and zinc die casting manufacture

- Precision implementation of your specifications

- Full project planning and handling

- Assessment and monitoring of the mould designs

- Complete take-over of transport and customs clearance as well as the commercial handling

- Injection tests, inspection and validation of the delivered moulds in Service/Mould Construction in Endingen

- Tools are rapidly and easily serviced, modified and repaired in the injection moulding centre