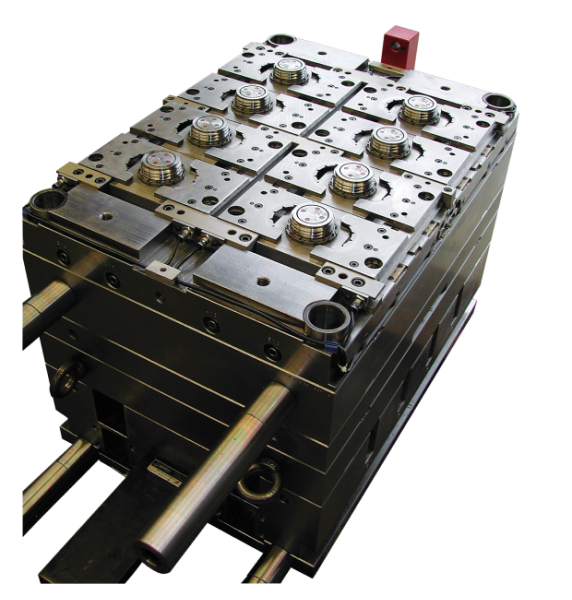

Showroom mould making and injection moulding

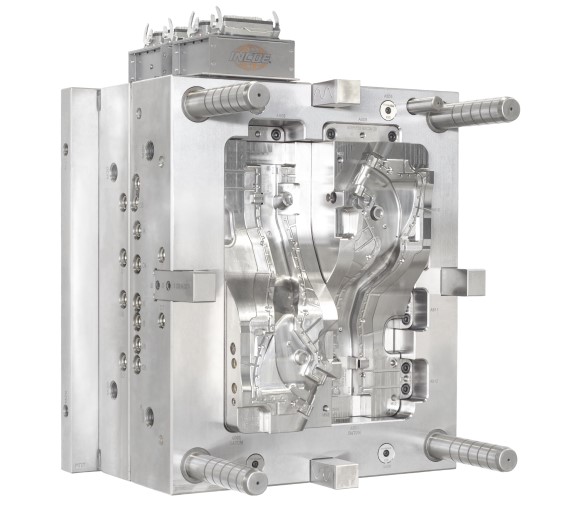

Mold making and injection molding automotive

Center console Mercedes Benz C-Class

General project parameters

- 28 injection moulding tools in the set

- Components for air ducts, air nozzles, cup holders, kinematics, light leads etc.

Materials used

- PC+ABS, PA6, POM, PC

Particular features of the injection moulding tools

- Very high requirements placed on surface structures

- Precision adjustment of all components one to the other

- Detailed, perfect design adjustments together with the purchaser

Lead times up to delivery of the injection moulding tools

- 4 weeks for all designs

- 10 weeks for complete tool manufacture following design approval

Resume

- Largest project scope to date as package for AsMoPLAST

- Highly satisfied customer thanks to quality, delivery date and service

Mould making and injection moulding in Germany

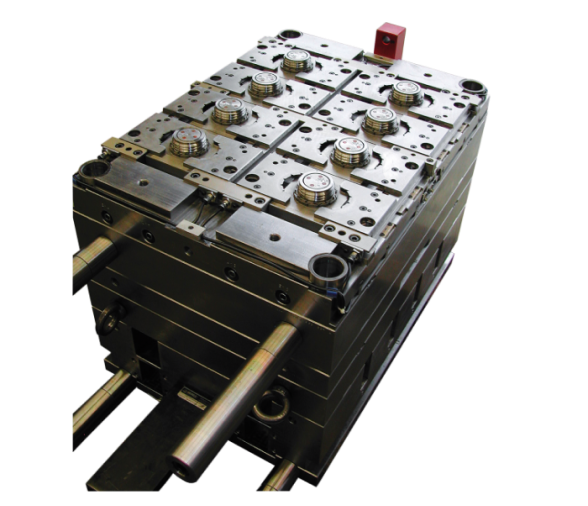

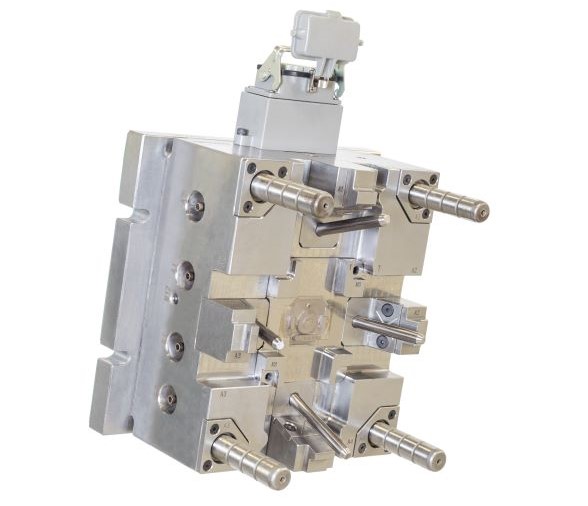

Holding clip automotive

Requirements profile:

Production of a follow-up tool for a holding clip with fir tree contour

Injection moulding tool production site:

Germany

Production site - injection moulded parts:

Germany

No. of cavities:

16

Dimensions and weight - injection moulding tool:

296x346x440 mm / 320 kgs

Lead time:

10 weeks from design to FOT

Plastics used:

PA66

Component weight:

0.8g

Case-Study:

Automotive - Holding clip

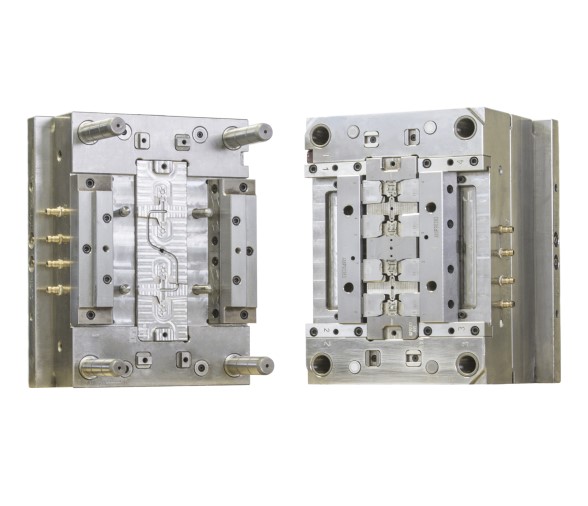

Mould making and injection moulding

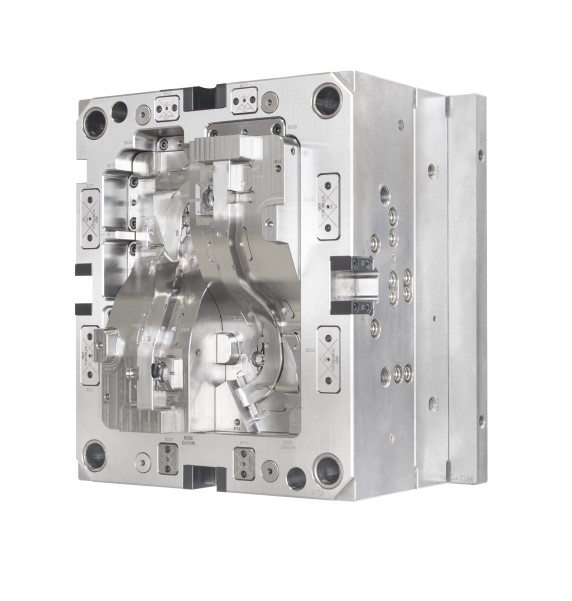

Automotive - Ventilation element

Branch:

Automotive

Requirements profile:

Manufacturing of 12 injection moulding tools in the technical field air duct and kinematics. High-precision coordination tuning of all parts

Manufacture - injection moulding tools:

China

Production site - injection moulded parts:

Germany

Durchlaufzeit:

8 weaks from design to FOT

Plastics used:

PC+ABS

Mould making in China

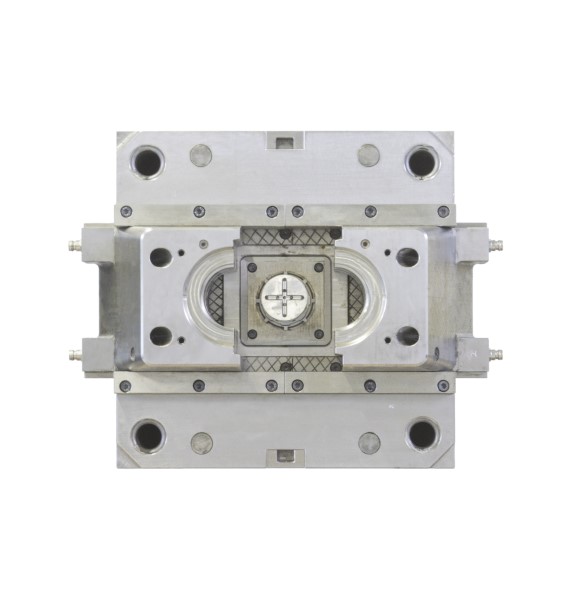

Automotive - Injection moulding parts

Branch:

Automotive

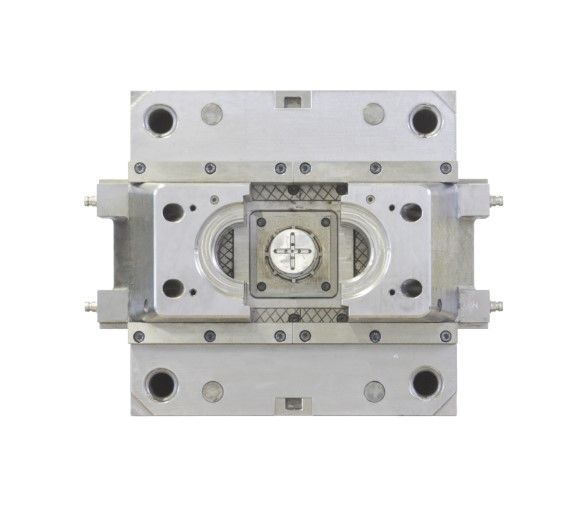

Requirements profile:

1 Injection moulding tool for producing injection moulding parts of a vehicle lighting

Production site - injection moulding tool:

China

No. of cavities:

1+1x

Dimensions and weight - injection moulding tool:

346x396x390 mm / 400 kgs

Lead time:

3 weeks design, 7 weeks production

Plastics used:

PC

Component weight:

15.7g

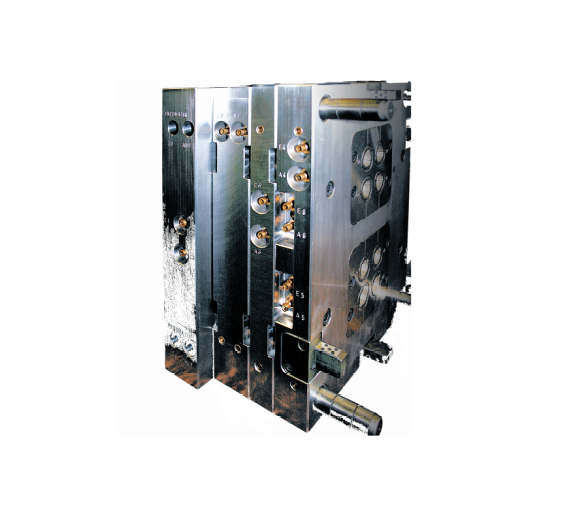

20 injection moulding tools China

Injection moulding, Cable ducts

Branch:

Automotive

Requirements profile:

Set of 20 injection moulding tools for cable ducts (electrical)

Manufacture - injection moulding tools:

China

Production site - injection moulded parts:

Morocco

No. of cavities:

2x and 4x

Weight:

250kg - 3000 kgs

Lead time:

11 weeks

Plastics used:

PP und PA6

Components weight:

2g to 60g

Injection moulding tools from China

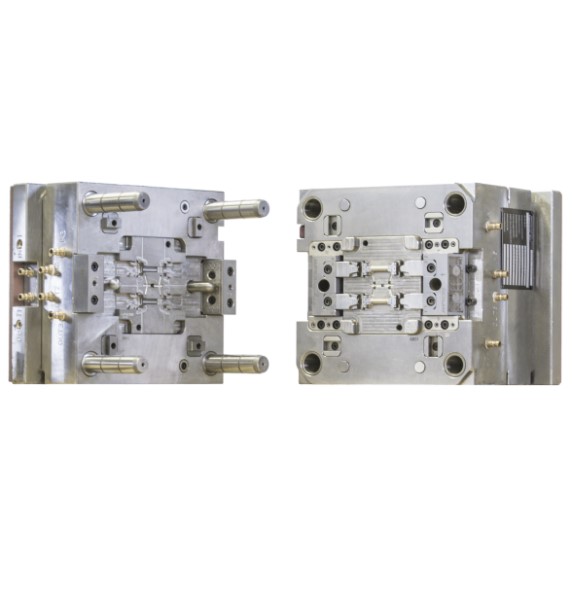

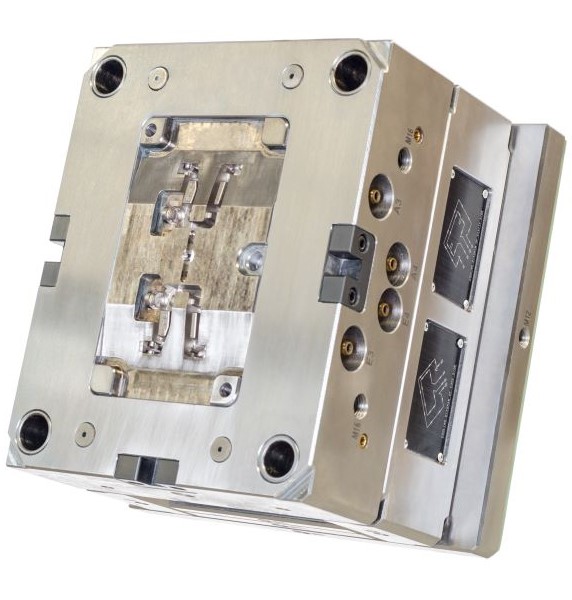

Injection moulding parts - Holding plates

Branch:

Electrical engineering

Requirements profile:

Set made up of four 1x tools with diverse change-over variants for housing and holding plates

Production site - injection moulding tools:

China

Production site - injection moulded parts:

At our customer’s in Germany

No. of cavities:

1

Dimensions and weight - injection moulding tools:

Up to 296x346x350mm / bis 290 kgs

Lead time:

3 weeks design, 8 weeks production

Plastics used:

PC

Components weight:

From 9.0g to 15.0g

Case-Study:

Electrical engineering - Holding plates

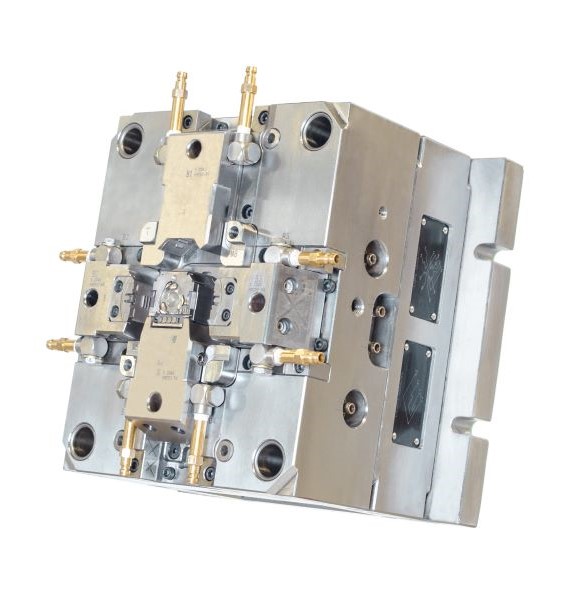

Mould making in Germany and China

Injection moulding parts - Housing

Branch:

Electrical engineering

Requirements profile:

Three tools for producing a housing with inner workings for a fibre glass connector

Production site - injection moulding tools:

China + Germany

Production site - injection moulded parts:

Germany

No. of cavities:

1x, 2xt, 1+1x

Weight - injection moulding tools:

150-350 kgs

Lead time:

8 weeks to FOT

Plastics used:

ABS

Components weight:

2-30g

Case-Study:

Electrical engineering - Housing

Mould making in China

Injection moulding parts - Plug housing 15-pin

Branch:

Electrical

Requirements profile:

2 injection moulding tools in a set including fully automatic thread demoulding

Production site - injection moulding tool:

China

No. of cavities:

2x

Dimensions and weight - injection moulding tool:

346x546x590 mm / 880 kgs

Lead time:

4 weeks design, 8 weeks production

Plastics used:

PA6 GF30

Component weight:

180g

Mould making in China

Injection moulding parts - Video intercom

Branch:

Electrical

Requirements profile:

4 injection moulding tools in a set

Production site - injection moulding tool:

China

No. of cavities:

1x and 1+1x

Dimensions and weight - injection moulding tool:

396x496x460 mm / 700 kgs

Lead time:

3 weeks design, 8 weeks production

Plastics used:

PC, PC+ABS

Mould making China

Component for electrical engineering

Branch:

Electrical engineering

Requirements profile:

2 injection moulding tools in a set. Manufacturing in China with 3 change-over variants, strict observance of all tolerances

Production site - injection moulding tools:

China

Production site - injection moulded parts:

Germany

No. of cavities:

1 with 3 change-over variants

Dimensions and weight - injection moulding tools:

246x296x360 mm / 200Kg

Lead time:

10 weaks

Plastics used:

PC

Components weight:

10g

Mould making in China

Injection moulding Germany - Cover holder

Branch:

Furniture industry

Requirements profile:

Tool set with 12 items in 7 tools Use of family tools for right-left parts

Production site - injection moulding tools:

China

Production site - injection moulded parts:

At AsMoPLAST in Germany

No. of cavities:

1+1 and 2x

Dimensions and weight - injection moulding tools:

Up to 346x396x350mm / up to 380 kgs

Lead time:

8 weeks from order to FOT

Plastics used:

PA6GF15, PC-ABS, ABS

Components weight:

5-30g

Mould making Germany

Injection moulding Germany, 2C strip

Branch:

Home / Garden

Requirements profile:

Manufacturing a 2C injection mould

Production site - injection moulding tool:

Germany

Production site - injection moulded parts:

At our customer’s in Germany

No. of cavities:

1x hard component, 1x soft component

Dimensions and weight - injection moulding tool:

496x796x680mm / 2.100 kgs

Lead time:

11 weeks

Plastics used:

PA6 GF30 + TPE

Components weight:

205g

Production of 17 moulding tools

Injection moulding parts, Baby milk maker

Branch:

Household

Requirements profile:

17 injection moulding tools in a set

Production site - injection moulding tools:

China

Production site - injection moulded parts:

Germany

No. of cavities:

1x tools

Injection moulding tools - dimensions:

Tool size up to 600x600x740mm

Lead time:

16 weeks

Plastics used:

ABS, PA6, TPE, SAN

Components weight:

Shot weight from 2.5g to 220g

Moulding tools from China

Injection moulding Germany, Hose reel

Branch:

Home / Garden

Requirements profile:

6 injection moulds in a set for a hose reel

Production site - injection moulding tools:

China

Production site - injection moulded parts:

At our customer’s in Germany

No. of cavities:

1x to 4x tools

Dimensions and weight - injection moulding tools:

Up to 896x996x800mm / up to 5,500 kgs

Lead time:

14 weeks

Plastics used:

PP and PA6 GF30

Size of components:

Ø450mm

Case-Study:

Consumer - Hose reel

2 component injection moulding tool from China

Injection moulding parts - 2C threaded ring

Branch:

Home

Requirements profile:

2 component injection moulding tool including fully automatic thread demoulding

Production site - injection moulding tool:

China

No. of cavities:

2x

Dimensions and weight - injection moulding tool:

496x496x520 mm / 1,000 kgs

Lead time:

4 weeks design, 8 weeks production

Plastics used:

PA6 GF30 + TPE

Component weight:

42g

3 moulding tools from China

Injection moulding - Lawnmower wheel panels

Branch:

Home

Requirements profile:

3 injection moulding tools in a set for wheel panels of a lawnmower

Production site - injection moulding tool:

China

No. of cavities:

1x and 2x

Dimensions and weight - injection moulding tool:

446x646x480 mm / 1,100 kgs

Lead time:

3 weeks design, 7 weeks production

Plastics used:

PP

Component weight:

59g

Furniture industry - injection moulding tools China

and plastic injection moulding Germany

Branch:

Furniture industry

Requirements profile:

Set of 2 injection moulding tools; fabrication in China under strict observance of all tolerances; production of the injection moulded parts with the assembly of a screw in Germany

Production site - injection moulding tools:

China

Production site - injection moulded parts:

Germany

No. of cavities:

2+2

Dimensions and weight - injection moulding tools:

346x396x315mm / 330Kg

Lead time:

10 weaks

Plastics used:

PA6 GF15

Components weight:

9,1g

Furniture industry - mould making China

Injection moulded parts Germany

Branch:

Furniture industry

Requirements profile:

Set of 2 injection moulding tools; fabrication in China under strict observance of all tolerances; production of the injection moulded parts with the assembly of a screw in Germany

Production site - injection moulding tools:

China

Production site - injection moulded parts:

Germany

No. of cavities:

1+1

Dimensions and weight - injection moulding tools:

246x296x305mm / 170 Kg

Lead time:

10 Wochen

Plastics used:

PA6 GF15

Components weight:

13,1g

9 moulding tools from China

Injection moulding Germany, Multiplier

Branch:

Medical

Requirements profile:

9 injection moulding tools with a total of 17 parts in a set

Production site - injection moulding tool:

China

No. of cavities:

1x and 1+1x

Weight - injection moulding tool:

70 kgs to 250 kgs

Lead time:

3 weeks design, 7 weeks production

Plastics used:

PC-ABS

Component weight:

1g to 28g

Case-Study:

Medical - Respiratory device

9 injection moulding tools China

Injection Moulding Germany, Measuring tube

Branch:

Medical

Requirements profile:

9 injection moulding tools with a total of 17 parts in a set

Production site - injection moulding tool:

China

No. of cavities:

1x and 1+1x

Weight - injection moulding tool:

70 kgs to 250 kgs

Lead time:

3 weeks design, 7 weeks production

Plastics used:

PC-ABS

Component weight:

1g to 28g

Mould construction in China

Measuring instrument housing

Branch:

Medical

Requirements profile:

1 injection moulding tool

Production site - injection moulding tool:

China

No. of cavities:

1+1x

Weight - injection moulding tool:

346x446x390 mm / 460 kgs

Lead time:

2 weeks design, 6 weeks production

Plastics used:

PC+ABS

2 component injection moulding tool from China

Injection moulding parts - 2C threaded ring

Branch:

Home

Requirements profile:

2 component injection moulding tool including fully automatic thread demoulding

Production site - injection moulding tool:

China

No. of cavities:

2x

Dimensions and weight - injection moulding tool:

496x496x520 mm / 1,000 kgs

Lead time:

4 weeks design, 8 weeks production

Plastics used:

PA6 GF30 + TPE

Component weight:

42g

Mould making China

2C seal - battery compartment

Branch:

Technical Parts

Requirements profile:

2-component plastic part for sealing a battery compartment Customer-requested manufacturing in the transfer method using two injection moulding tools for hard and soft components

Production site - injection moulding tool:

China

No. of cavities:

1x in each instance

Dimensions and weight - injection moulding tool:

296x296x320 mm / 220 kgs

Lead time:

3 weeks design, 6 weeks production

Plastics used:

ABS + TPE

Component weight:

Hard component 14.8g / soft component 1.7g

20 injection moulding tools China

Injection moulding, Cable ducts

Branch:

Automotive

Requirements profile:

Set of 20 injection moulding tools for cable ducts (electrical)

Manufacture - injection moulding tools:

China

Production site - injection moulded parts:

Morocco

No. of cavities:

2x and 4x

Weight:

250kg - 3000 kgs

Lead time:

11 weeks

Plastics used:

PP und PA6

Components weight:

2g to 60g

Mould making Germany and China

Injection moulding parts Germany, Inserts

Branch:

Packaging / seals, cosmetics

Requirements profile:

12x high volume production mould for production of a cosmetics package

Production site - injection moulding tool:

China + Germany

Production site - injection moulded parts:

Germany

No. of cavities:

12

Dimensions and weight - injection moulding tool:

546x296x550mm, 720kgs

Lead time:

10 weeks to FOT (incl. design, manufacturing and tool despatch)

Plastics used:

PP

Components weight:

5g

Case-Study:

Caps/Closures - Inserts

Moulding injection tools from China

Moulding injection parts, Dosing seal

Branch:

Packaging / seals

Requirements profile:

6 multi-cavities injection moulding tools for maximum output quantities and small components with high precision

Production site - injection moulding tools:

China

Production site - injection moulded parts:

Switzerland

No. of cavities:

4x and 8x

Dimensions and weight - injection moulding tools:

from 196x196x300mm to 296x496x420mm / from 90 kgs to 480 kgs

Lead time:

14 weeks

Plastics used:

TPE, PET, LDPE, PE HD, PP

Components weight:

From 0.12g to 1.15g

Case-Study:

Caps/Closures - Dosing seal

3 injection moulding tools China

Injection moulding, Sieve

Branch:

Diverse

Requirements profile:

3 injection moulding tools in a set for re-injection of a metal mesh

Production site - injection moulding tool:

China

No. of cavities:

2x

Dimensions and weight - injection moulding tool:

216x396x370 mm / 240 kgs

Lead time:

3 weeks design, 6 weeks production

Plastics used:

POM

Component weight:

14.6g

2c injection moulding tools China

Injection moulding, Housing parts - hearing aid

Branch:

Diverse

Requirements profile:

7 injection moulding tools incl also 2-component injection moulding tools totalling 12 parts in a set

Production site - injection moulding tool:

China

No. of cavities:

2+2x, 2+2+2x, 2x and 4x

Dimensions and weight of injection moulding tool:

up to 246x296x300 mm / 170kgs

Lead time:

4 weeks design, 7 weeks production

Plastics used:

ABS + TPE

Component weight:

0.2g to 4.6g

Requirements profile:

Injection moulding tools for a battery compartment

Manufacture - injection moulding tools:

China

No. of cavities:

1

Lead time:

3 weeks design; 8 weeks production

Particular features:

- Large hydraulic cylinder to “pull” the inner core

- Long inner core is isolated and due to the parts geometry cannot be supported; thus maximum requirements placed on the gating of this item to prevent displacement of the inner core during the injection.

Requirements profile:

Injection moulding tools for a 2C plug housing

Manufacture - injection moulding tools:

China

No. of cavities:

1

Lead time:

3 weeks design; 6 weeks production

Particular features:

- Injection tool for re-injection of a TPE seal to an existing plastic part

- Injection tool adjustment to the existing pre-injection moulded piece

Requirements profile:

Injection moulding tools for a plug housing

Manufacture - injection moulding tools:

China

No. of cavities:

4

Lead time:

3 weeks design; 6 weeks production

Particular features:

- Jaw tool for small electronics components

- Tight tolerances at the item obtained from several correction loops

- Item had to be adjusted with its counter piece

Requirements profile:

Injection moulding tool for a plug housing, a plug base

Manufacture - injection moulding tools:

China

No. of cavities:

4

Lead time:

3 weeks design; 6 weeks production

Particular features:

- Slider tool for small electronics components

- Tight tolerances at the item obtained from several correction loops

- Item had to be adjusted with its counter piece

Requirements profile:

Injection moulding tool for a screwed cap

Manufacture - injection moulding tools:

Germany

No. of cavities:

8

Lead time:

5 weeks design; 11 weeks production

Particular features:

- Fully automatic thread unscrewing

- Threaded spindles with integrated core cooling

- Deployment for ultra-hot conductible materials for quicker cycle times

- Mould slider for shaping the guarantee band at the seal cap

- Maximum requirements placed on tolerances and surfaces

- Gating directly onto the item using the hot runner

Requirements profile:

Injection moulding tool for a 2C locking screw

Manufacture - injection moulding tools:

Germany

No. of cavities:

4+4

Lead time:

4 weeks design; 9 weeks production

Particular features:

- 2C injection tool for rotary plate usage

- Plastic: PA6 and TPE with 60 Shore

- Gating with open hot runner for the PA6 and hot runner needle valve for the TPE

Requirements profile:

Injection moulding tool for the bottom shell of a remote control

Manufacture - injection moulding tools:

Germany

No. of cavities:

1

Lead time:

4 weeks design; 8 weeks production

Particular features:

- Tight tolerances at the item obtained from several correction loops

- Item had to be adjusted with its counter piece

- Maximum requirement placed on the eroded surface

Branch:

Medical

Requirements profile:

New injection moulding tool from our production site in Germany for a packaging as a replacement for a purchase part.

Manufacture - injection moulding tools:

Germany

No. of cavities:

2

Weight - injection moulding tools:

100Kg

Lead time:

9 weaks from order to FOT

Branch:

Automotive

Requirements profile:

Production of a follow-up tool in Germany for cable ducts.

Manufacture - injection moulding tools:

Germany

No. of cavities:

2

Dimensions and weight - injection moulding tools:

240Kg

Lead time:

10 weaks from order to FOT

Branch:

Automotive

Requirements profile:

Production of an injection moulding tool as a remplacement for an existing tool.

Manufacture - injection moulding tools:

China

No. of cavities:

2

Dimensions and weight - injection moulding tool:

170-350Kg

Lead time:

9 weeks from design to FOT

Branch:

Furniture industry

Requirements profile:

Set of 2 injection moulding tools; fabrication in China under strict observance of all tolerances

Fabrication - injection moulding tools:

China

No. of cavities:

1+1

Dimensions and weight - injection moulding tools:

246x296x305mm / 170 Kg

Lead time:

10 weaks

Branch:

Furniture industry

Requirements profile:

Set of 2 injection moulding tools; fabrication in China under strict observance of all tolerances

Fabrication - injection moulding tools:

China

No. of cavities:

2+2

Dimensions and weight - injection moulding tools:

346x396x315mm / 330Kg

Lead time:

10 weaks

Branch:

Technical engineering

Requirements profile:

2 injection moulding tools in a set. Manufacturing in China with 3 change-over variants, strict observance of all tolerances

Fabrication - injection moulding tools:

China

No. of cavities:

1 with 3 change-over variants

Dimensions and weight - injection moulding tools:

246x296x360 mm / 200Kg

Lead time:

10 weaks

Branch:

Automotive

Requirements profile:

4 injection moulding tools in a set for the production of safety parts; very high requirements placed on tolerances

Manufacture - injection moulding tools:

China

No. of cavities:

8

Dimensions and weight - injection moulding tool:

246x346x285mm / 180Kg

Lead time:

12 weaks

Branch:

Automotive

Requirements profile:

4 injection moulding tools in a set for the production of safety parts; very high requirements placed on tolerances

Manufacture - injection moulding tools:

China

No. of cavities:

8

Dimensions and weight - injection moulding tool:

246x296x285mm / 160 Kg

Lead time:

11 weaks