Security

Moulding in China / Security China

Utilize the chances. Avoid the risks.

Manufacturing in China is still confronted, in part, by considerable scepticism. Expectations and reality sometimes drift far apart with ostensibly low-cost production turning out to be an expensive luxury. Anything is possible from non-kept promises, production shortcomings and no delivery effectiveness.

Only a market leader such as AsMoPLAST with its own production capacities lets you calmly contemplate a production undertaking in China. Only in this way can the incontestable cost and delivery time benefits be fully exploited.

German company, AsMoPLAST Engineering GmbH, is ready to assume the contractual role. This removes all legal and guarantee uncertainties. Ultra-modern machinery, excellent operating personnel and our on-site presence all ensure a high level of production With AsMoPLAST you’ll sleep well with a Far East production project involved - that’s a promise.

Your benefits with AsMoPLAST in China

You don’t need to deal with anything - our team will do it for you. Our overall package makes mould construction simple, secure, punctual and low cost for you in China.

- A German contract partner means: absolute legal security, same guarantees and warranties as in Germany

- No problems from language barriers, mentality and market knowledge gaps, costly misunderstandings are ruled out

- Constant presence and on-site monitoring of all processes ensure adherence to delivery dates and quality standards

- Specifications are precision-implemented to very attractive delivery and price benefits

- All injection moulds from China are DIN ISO 9001-certificated

- Assured and effective utilization of practically unlimited opportunities in manufacturing injection moulding and prototype tools

Contract reliance as a quality feature

The legal situation often presents an insurmountable barrier for companies. Companies could well flounder given a direct purchase in China or an order undertaken through a dealer only. A lack of transparency and contract reliance sometimes result in nightmares experienced. On the other hand, our customers sleep very well. Contract partner AsMoPLAST Engineering GmbH is a German company with all the attendant warranties.

The associated respectability ensures absolute security in all legal issues. For production undertakings in China, we expressly recommend turning to a partner who is at home on both the markets. And this partner is AsMoPLAST.

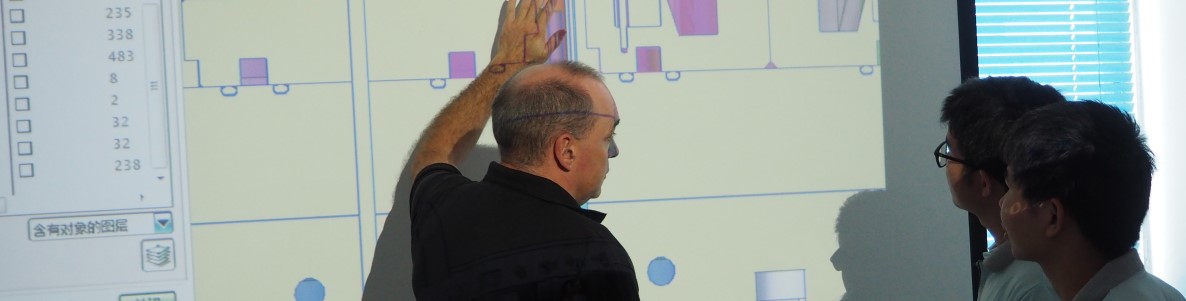

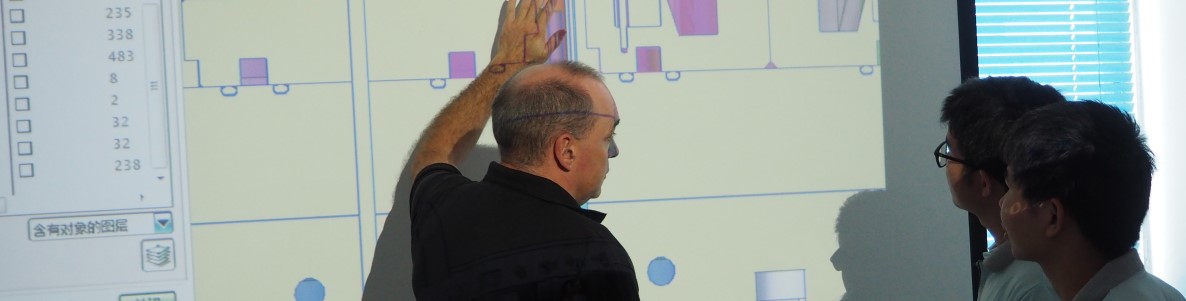

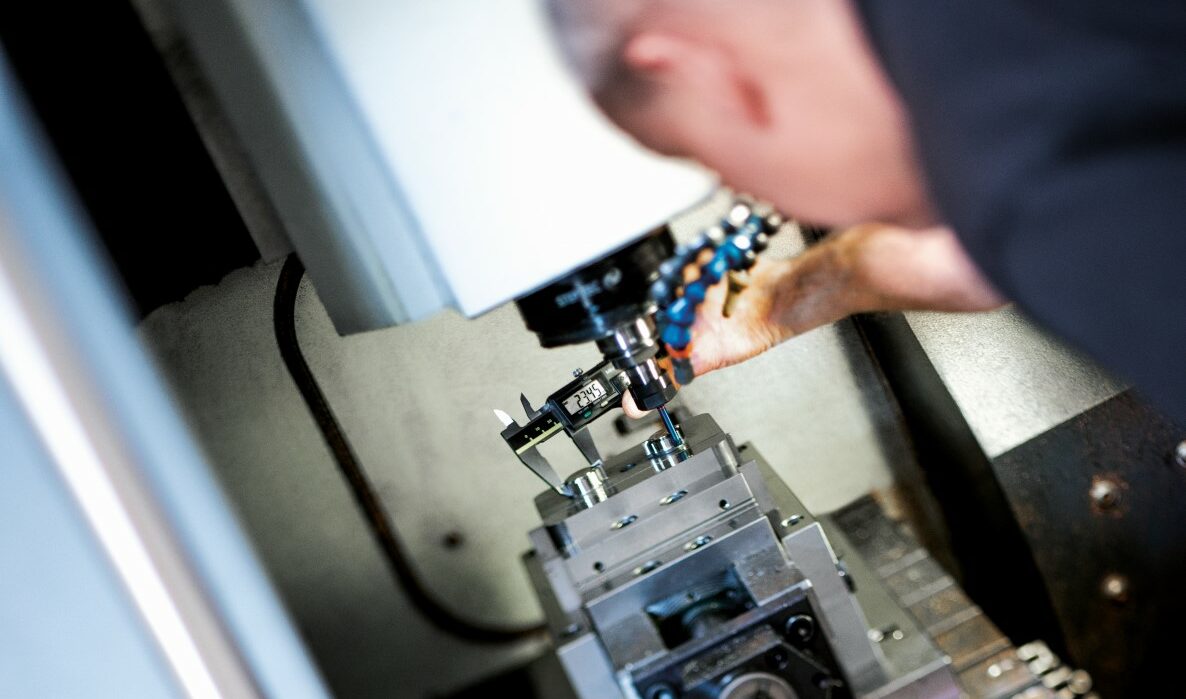

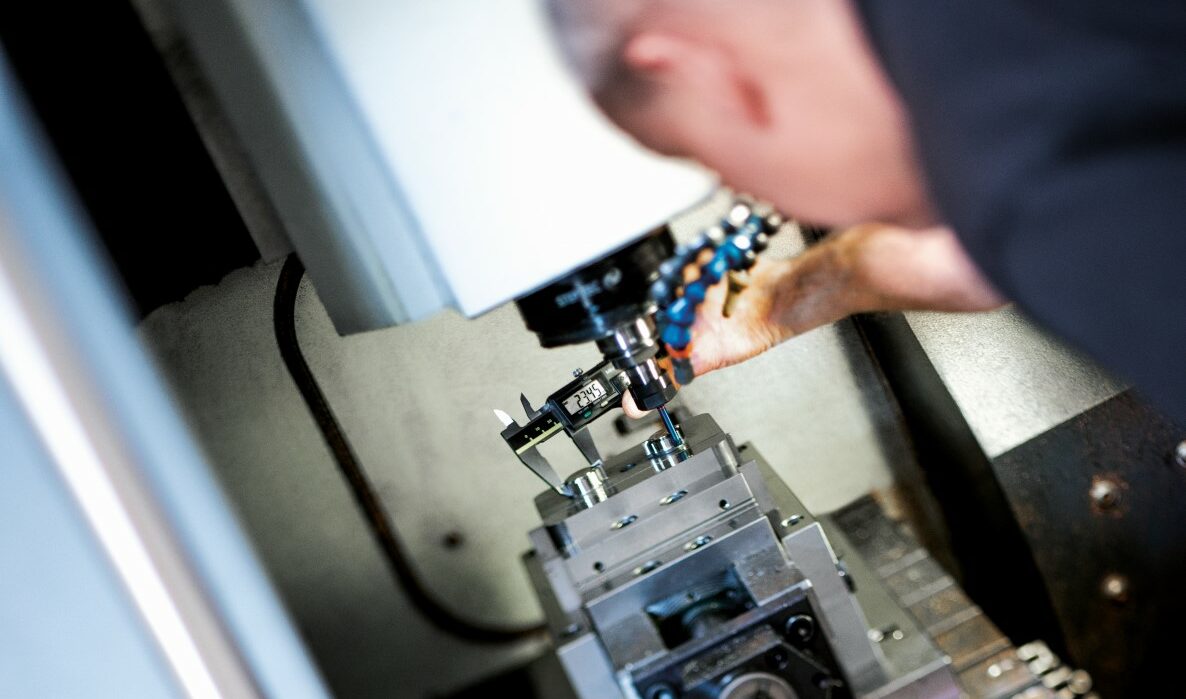

Quality and delivery reliability

Know-how made in Germany – that is what you expect when cooperating with AsMoPLAST and even more when injection moulding tools are to be produced in China. We control and monitor the entire process from project planning and manufacturing through to the actual delivery. This ensures quality in all the phases. Decisive components for success are able project management, long-term, evolved partnerships in China and an irreplaceable on-site presence.

We have these components and can thus fulfil your expectations. Whether technically more challenging injection moulding tools or multi-component/prototype tools with rapid realization times are involved. Inclusive of guaranteed delivery and quality reliability.

After-sales service

Purchasing in China is completed and the moulding tool delivered. And now what? Often minor corrections need to be carried out, parts adjusted and the tool serviced. As this usually needs to be done quickly, sending it back to China is really not an option.

For our customers we have a comprehensive all-inclusive after-sales service offer in the Endingen injection moulding centre and the attached injection moulding technical centre. Any company purchasing in China should pay attention to this follow-through aspect. AsmoPLAST allows you to have your injection moulding tools made in China and then directly deploy them for your injection moulded part series production.