LSR injection moulding

Made in germany / LSR injection moulding

LSR injection moulding technology and AsMoPLAST - a masterly duo

The demand for silicone parts is continuing to grow given the impressive benefits and the very diverse operational fields. In particular, the comparatively new LSR injection moulding technology provides far-reaching opportunities which will delight us all.

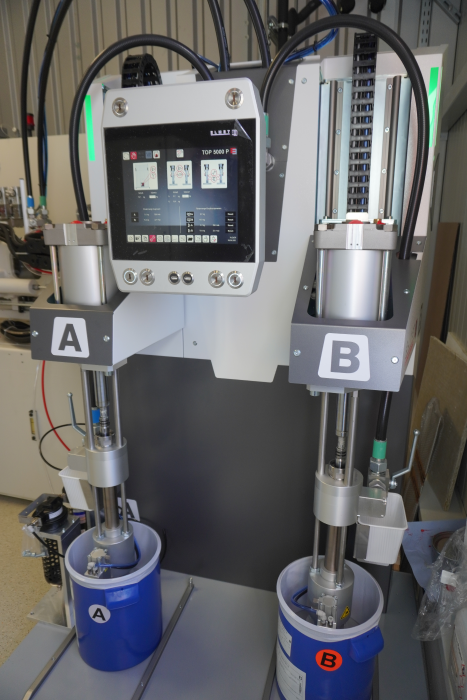

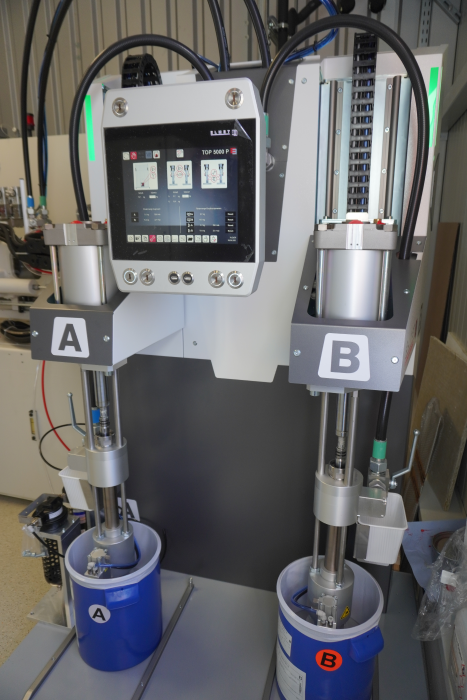

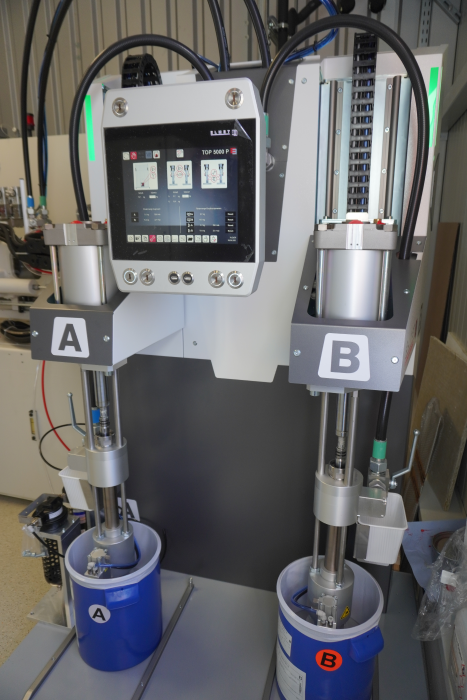

The brand-new CX80 SilcoSet injection moulding machine from KraussMaffei and the Elmet Co. dosing facility show the confidence we have in the absolute specialists from the outset in matters of LSR injection moulding. Only the best possible equipment ensures the perfect quality of your silicone injection moulded parts. And AsMoPLAST stands for just that.

Together with the dual AsMoPLAST system we again set the standards. Thanks to our production capacities in high-tech mould construction in China, we can produce almost anything for you from straightforward to highly complex LSR injection moulding tools. Done reliably, quickly and at high-grade technical level.

We would be happy to help you in all questions - just get in touch with us!

Profile - LSR injection moulding technology

- Comprehensive consulting on your LSR parts for the application field in question.

- Decisive support in product and process development with AsMoPLAST Engineering.

- Security thanks to manifold possibilities we have in prototype tools.

- Manufacturing LSR injection moulding tools of whatever type in High-tech China mould construction.

- Manufacturing first prototypes of your silicone injection moulded parts as pre-series and small batches.

- Production of silicone injection moulded parts in small or large quantities for all intended uses in the required finish, surface feel and optical characteristics.

- The high-grade equipment ensures process reliability, quality and precision.

- A wide variety of services in surface finishing and machining your silicone parts.

- Maintenance and storage of your LSR injection moulding tools, just-in-time delivery of the silicone injection moulded parts.

Silicone injection moulding benefits and scope

- Parts made of silicone have excellent mechanical, thermal and chemical properties.

- Silicone parts are noted for their permanent elasticity and a high elongation at break which result in remarkable mechanical resilience.

- Silicone parts can be sterilised thanks to their temperature stability.

- Silicone made injection moulded parts are bio-compatible, bacterially resistant and neutral in taste.

- The absence of softeners clearly extends the scope of application.

- Another distinguishing feature of silicone parts are their long service lives.

- The low viscosity of liquid silicone provides it with good flow properties.

Equipment – We only trust the best

The brand-new CX80 SilcoSet injection moulding machine from KraussMaffei and the Elmet Co. dosing facility provides us with excellent equipment at the Endingen injection moulding centre. Since we want to ensure you continue to get the best-possible quality and reliability.

After all, the two companies are the cutting-edge experts in LSR injection moulding technology. This is hugely important particularly in silicone technology. Silicones - and especially the new liquid silicone generations (LSR, Liquid Silicone Rubber) require a maximum degree of precision and process stability. And in addition, excellent equipment is needed alongside AsMoPLAST’s expertise in mould construction and injection moulding. The benefits:

- Assured stable processing of low viscous material thanks to absolute plate parallelism.

- Exact shot weight constancy.

- Constantly high component quality and thus minimum ejection thanks to APC plus.

- Digital solutions providing absolute transparency across the entire process.

- Water-cooled, pneumatic needle valve nozzles for process-reliable material feed with every shot.

- Compensation of charge variations and viscosity differences with innovative process control.

- Special non-return valves matched to the respective material requirements.