Injection moulding centre

Made in germany / Injection moulding centre

Moulding Is Our Mission.

Injection moulding from Germany

Moulding Is Our Mission. What does that mean in fact? As ever, AsMoPLAST’s goal has been to deliver the best possible performance for you. To provide you exactly with the work and services in Mould Construction and Injection Moulding which you need at the moment. We pursue this mission consistently and resolutely. This resulted in the construction of a modern production bay with all technical refinements in 2018.

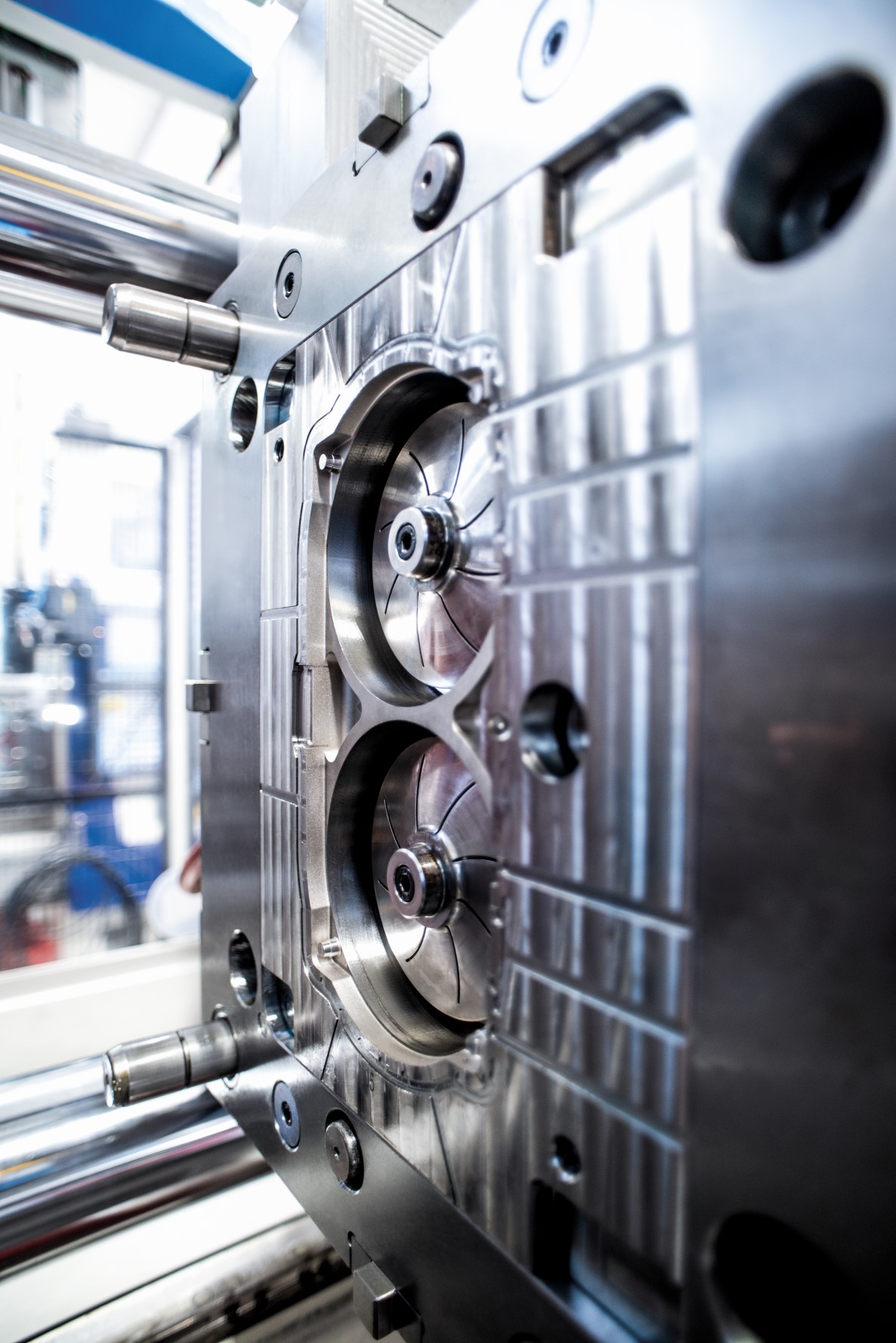

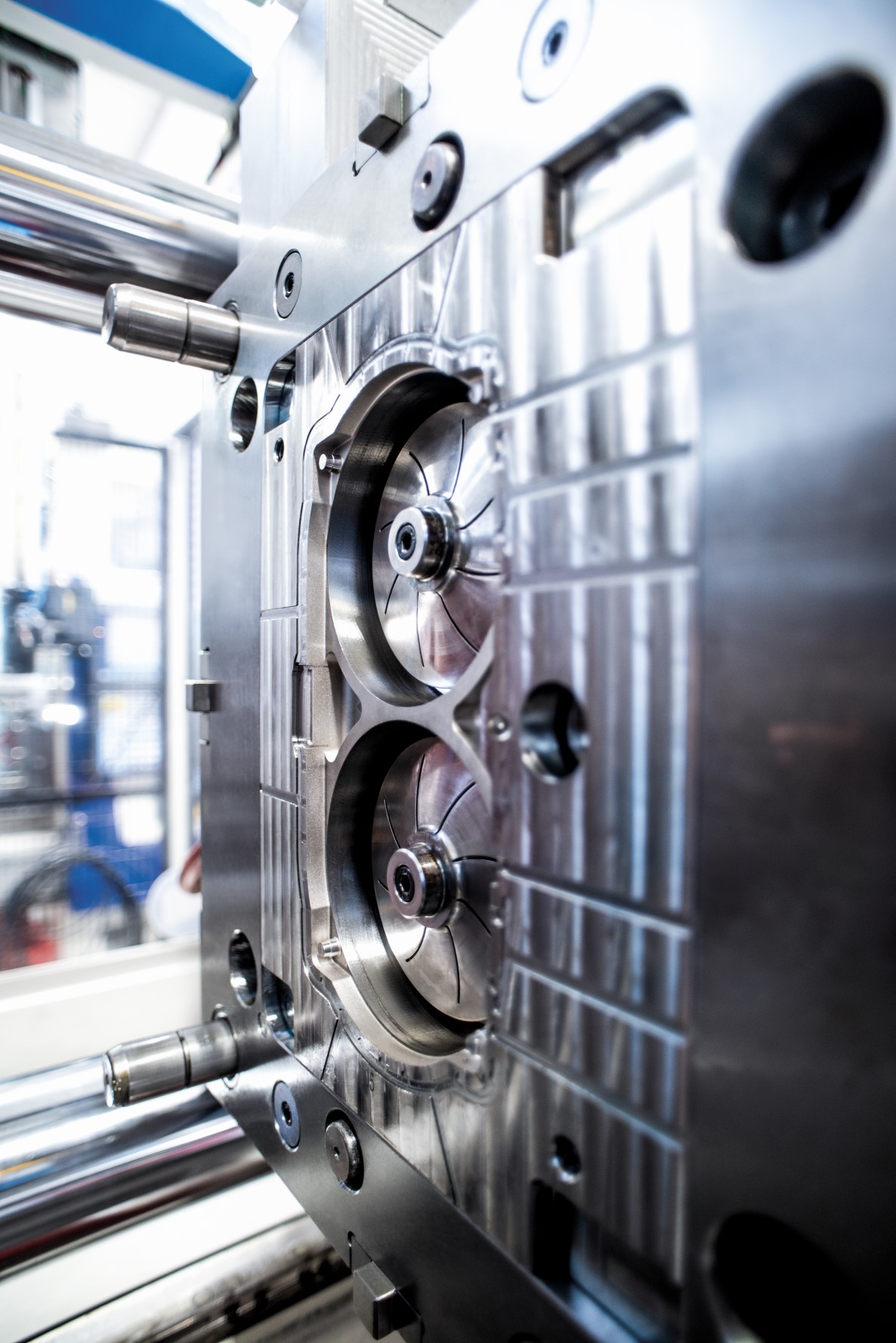

At the Endingen injection moulding centre you will experience a top performance and ideal conditions for your series production. Our injection moulding parts, which can be produced in practically all plastics, meet all requirements regarding functionality, intended use and design. For every industry and intended use we manufacture the ideally appropriate products. Our speciality covers, in particular, the production of small to medium quantities.

Prior to series production, your requirements are taken up with all due care and integrated into the planning. Injection tests with various raw materials and colours, production of pre-series and comprehensive function tests safeguard your series production.

Profile of injection moulding technology - Our portfolio at a glance

Injection moulding technical centre

- Establishing optimum parameters for stable processes

- Application-related consultation on the injection moulding process

- Injection tests with various raw materials and colours

- Production of pilot or production start-up series

- Injection moulding pre-series in small to medium-sized lots in the original plastic

- Carrying out works acceptance inspections

- Test and change sampling inspections

Series production

- Series production of your injection moulded parts from small lots to batches in their millions

- High-grade, pan-industry injection moulded parts

- Challenging plastic parts for multiple applications

- Injection moulded parts in striking optical characteristics

- Injection moulded parts with a particular requirements profile, e.g. surface feel

- Industrial injection moulded parts

- Multi-component injection moulded parts

- Contract manufacturing

- Processing a large section of the available materials

- Processing practically all thermoplastics

- Silicone processing

Supplementary work & services

- Various printing operations

- Various paint finishes

- Hot stamping

- Laser labelling

- Ultrasonic welding

- Module assembly

- Manual work: De-burring, drilling, cutting, turning etc.

Injection moulding technical centre

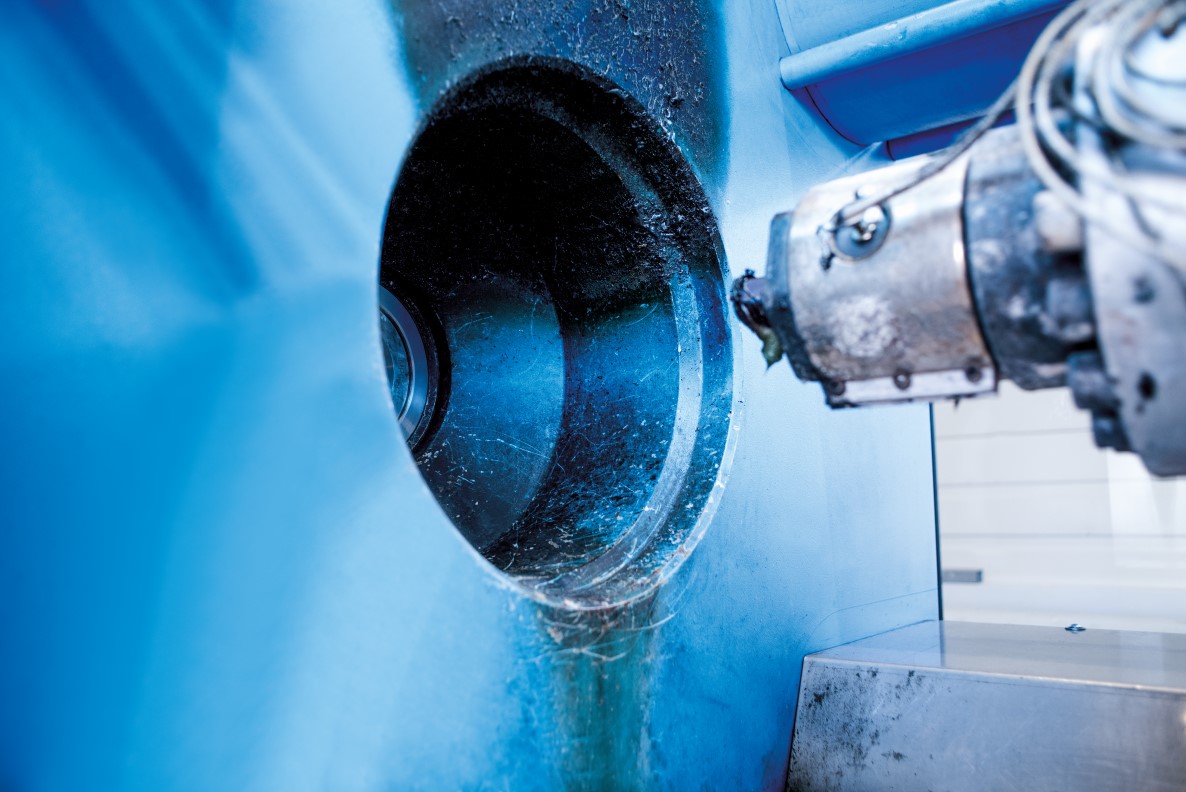

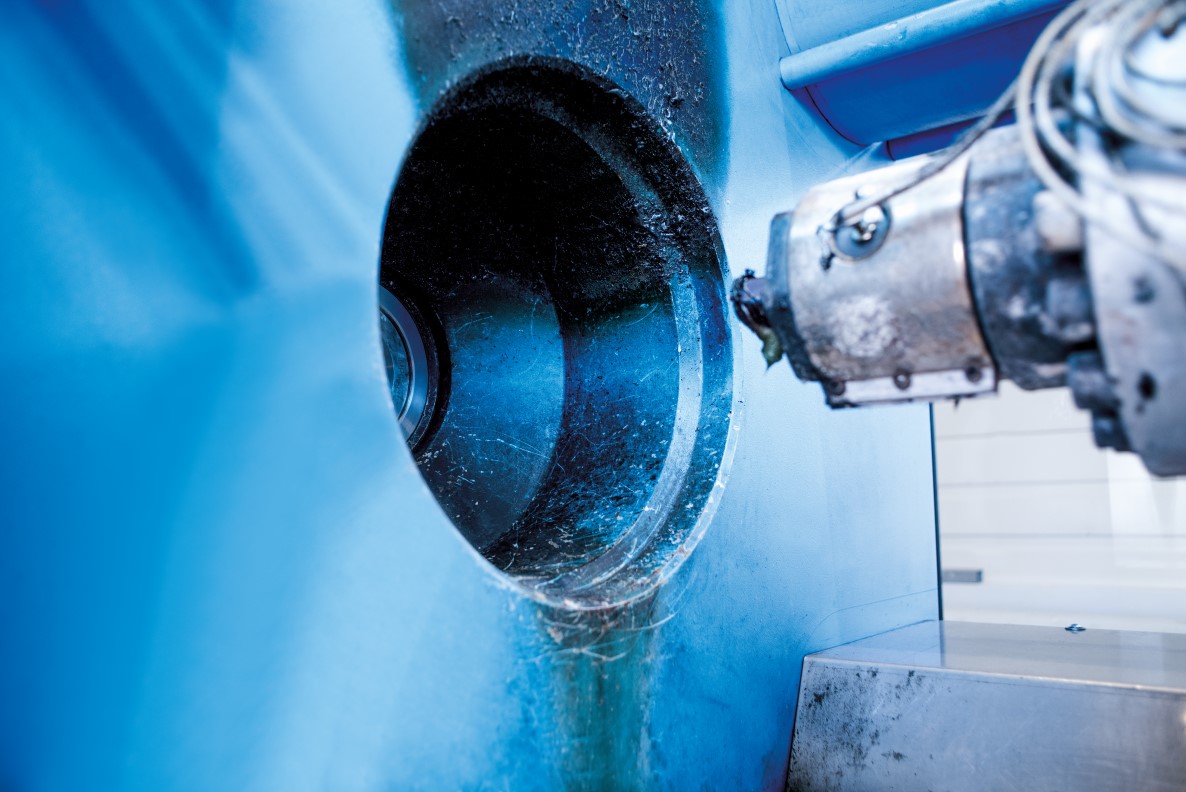

The Endingen injection moulding centre ensures that your requirements are taken up with all due care and integrated into the planning before the series production. Extensive, application related consultation, injection tests with various raw materials and colours or injection moulding pre-series in small to medium sized lots in the original plastic can be undertaken in our injection moulding technical centre.

Early-on quality checks, item optimization and customized consulting are especially crucial with injection moulding parts with difficult requirements such as tailor-made ones. At the Endingen injection moulding technical centre your planning and design can be intensively checked before the cost-intensive series production begins. All parameters for stable processes and economically optimum manufacturing methods are evaluated. Even at the preliminary stage you save a lot of money and gain on security.

Series production of injection moulding parts

The series production of your injection moulded parts couldn’t be in better hands. We also have no problem in producing small to medium sized lots. Thanks to minimize lead times and appropriate automation you are guaranteed a manufacturing process from a single source. Our machines run 24 hours a day, 7 days a week. This ensures scheduled deliveries for our customers.

Our particular strength is based on the harmonious interaction of our expertise in mould construction, development, injection moulding and in extra work and services such as module assembly. Thanks to our comprehensive work and services you profit from considerable cost savings and smooth-running processes.

We have gained substantial expertise particularly in the automotive and electrical engineering industries. One of our biggest strengths is the production of complete modules with up to 30 injection tools in one set.

Work and services around your injection moulded parts

The operational field often requires injection moulded parts to be finished in line with a customized requirements profile. For your functional or decorative requirements we can offer you a wide scope in printing and coating the injection moulded parts.

Furthermore, the injection moulded parts can be provided with additional components at the Endingen site. You can, of course, fall back on our services in module assembly and with customized packaging.