Our Story

Global Player / Our Story

Our Story

According to Simon Zügel, entrepreneurship is “in his genes”. For the eight-year-old youngster, his parents’ firm was just a huge playground (not always to the delight of his parents. What he has become aware of from this time and from the years that followed: Enjoyment in leading and being responsible for initiating motivation and taking decisions.

For Simon Zügel it is an honour - together with his wife Katharina - to continue the tradition of the undertaking and to dedicate himself to successfully preparing the family business for current and future challenges. Milestones have again and again been set to fully attain these goals.

2001

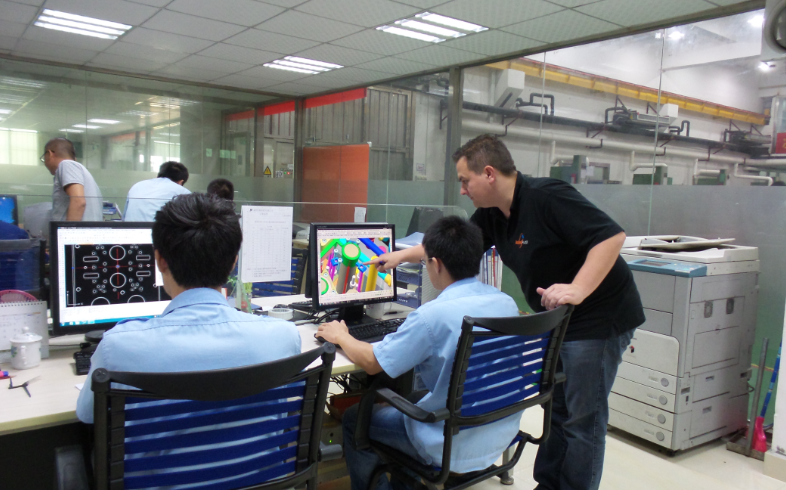

First China trip by Simon Zügel, study trip into the opportunities in mould construction and injection moulding technology.

2002

Even then first-ever production of an injection moulding tool in China. It was a complete failure, nothing fitted. He became aware that more development work than expected was necessary for production in China.

2004/2005

He needed three more years after the first project award for China to really understand mentality, sequences and the technical scope available in China. We stayed the course to guarantee our customers stability in manufacturing coupled with economic benefits.

2007

Establishing AsMoPLAST International Consulting in Hong Kong for improved organisational and administrative handling.

2010

Establishing AsMoPLAST Engineering GmbH in Germany as a project office only. To provide our business partners with the dependability, guarantees and warranties of a German company.

2011

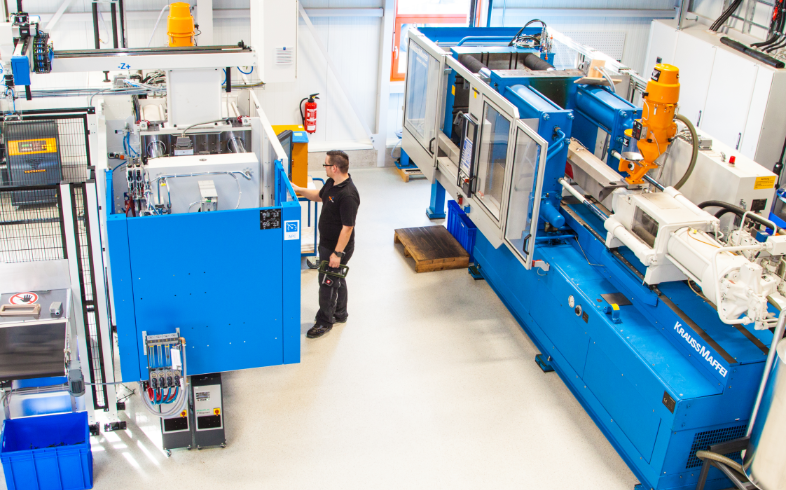

Establishing initial production capacities with tool test and reworking tools in Germany to have added values on offer

2012

Own-company site in Germany with administration and production bay with ample scope for manufacturing

2013

Major project from Daimler for over 30 tools and a total value of EUR 3 million

2015

Purchasing a CNC milling machine with a 300-ton closing force, successive extension of the scope of production

2018

Extension of the production bay at the injection moulding centre, doubling the production surface area

2020

Installation of a photovoltaic unit for CO2-neutral production

2021

Extending business activities, purchasing the first LSR machine for producing silicone injection moulded parts

2022

New construction of a production building. Significant expansion of the production capacities of mould making and plastic injection moulding.