Injection moulding tools China

Consumer Baby milk maker

Consumer - Baby milk maker

Case study injection moulding tools China

General project parameters

The order comprised a huge tool set made up of 17 injection moulding tools. The moulds were manufactured entirely in China.

Important: To coordinate matters perfectly, the AsMoPLAST project team travelled to China together with the customer. Together at the on-site sample inspection, the required adjustments and optimizations were defined and faultlessly implemented. There were then no problems in producing the injection moulding small batches at AsMoPLAST Deutschland.

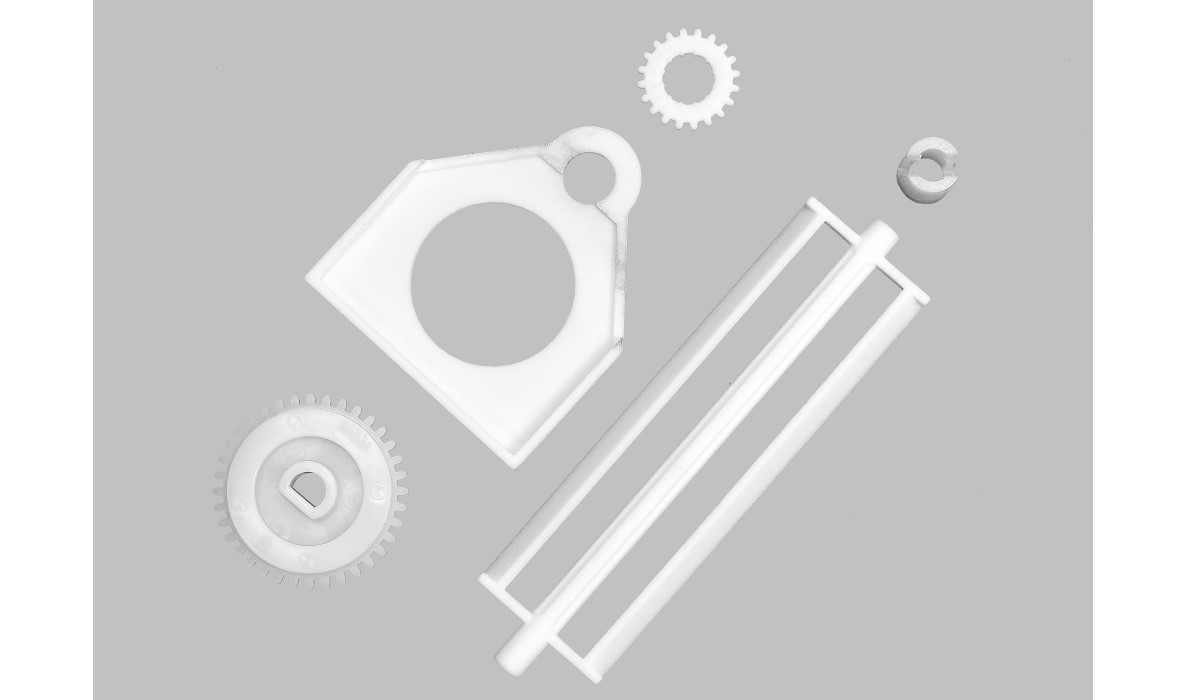

Description - Injection moulding tools

- Tool making in China.

- Manufacturing seventeen1x injection moulding tools

- Visible surfaces highly gloss-polished

Description - Injection moulded parts

- The injection moulded parts were manufactured with ABS, PA6, TPE, SAN plastics.

- The surface finishing represented a particular challenge.

- Most of them are visible and thus high standards are placed on optical characteristics of the surfaces.

- To comply with them, the plastic parts affected are high-gloss polished.

Interview with Mister Riedinger, CEO Milquino (German, pdf, 1,4 MB)

Branch:

Household

Requirements profile:

17 injection moulding tools in a set

Production site - injection moulding tools:

China

Production site - injection moulded parts:

Germany

No. of cavities:

1x tools

Injection moulding tools - dimensions:

Tool size up to 600x600x740mm

Lead time:

16 weeks

Plastics used:

ABS, PA6, TPE, SAN

Components weight:

Shot weight from 2.5g to 220g